The production process of 50D polyester interlining series is a complex and precise process, involving multiple links and technologies. The following is a detailed introduction to the production process of the 50D polyester interlining series:

Raw material preparation: The first step in producing 50D polyester interlining is to prepare raw materials. Polyester is a type of synthetic fiber, usually made from polyester compounds. The polyester fiber required to produce 50D polyester interlining needs to be strictly screened and processed to ensure its quality and stability.

Spinning: After the raw material preparation is completed, the next step is the spinning stage. At this stage, polyester fibers are spun into yarn. 50D polyester yarns are generally finer, so special spinning equipment and techniques are required to ensure yarn uniformity and quality.

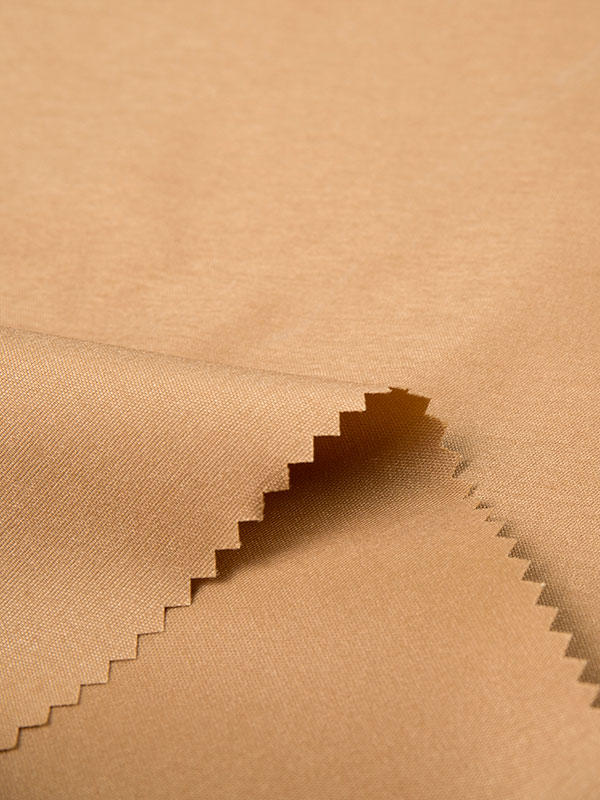

Weaving: After spinning is completed, the yarn is sent to the loom for weaving. Looms weave yarn into pieces of cloth according to design patterns and specifications. In the production of 50D polyester interlining series, specific fabric structure and density are usually used to ensure that the interlining has the required softness, breathability and durability.

Coating treatment (optional): Some 50D polyester interlinings may need to be coated to add specific properties, such as waterproof, anti-fouling or anti-bacterial. Coating is usually made by applying special coating materials or compounds on the surface of the lining cloth and heating or curing to form a protective layer.

Post-finishing: After the interlining is produced, a post-finishing process may be required to improve its appearance and feel. Post-finishing can include dyeing, printing, hot stamping and other processes, as well as shaping, finishing and other steps to achieve the final appearance and texture of the interlining.

Quality inspection: Strict quality inspection is required at every stage of interlining production to ensure that the product meets standards and specifications. This includes inspection of raw materials, spot checks during production, and comprehensive inspection of the final product.

Packaging and leaving the factory: Finally, through packaging and labeling, the finished 50D polyester interlining is packaged and ready to be sent to sales channels or customers. During the packaging process, the lining needs to be protected and secure to prevent damage during transportation and storage.

The production of 50D polyester interlining series involves multiple links and processes such as raw material preparation, spinning, weaving, coating treatment (optional), finishing, quality inspection, packaging and delivery. Each link requires sophisticated equipment and technology to ensure that the final product meets quality and performance standards. This process requires close coordination and management to ensure production efficiency and product quality.

English

English 中文简体

中文简体 Français

Français Español

Español.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)