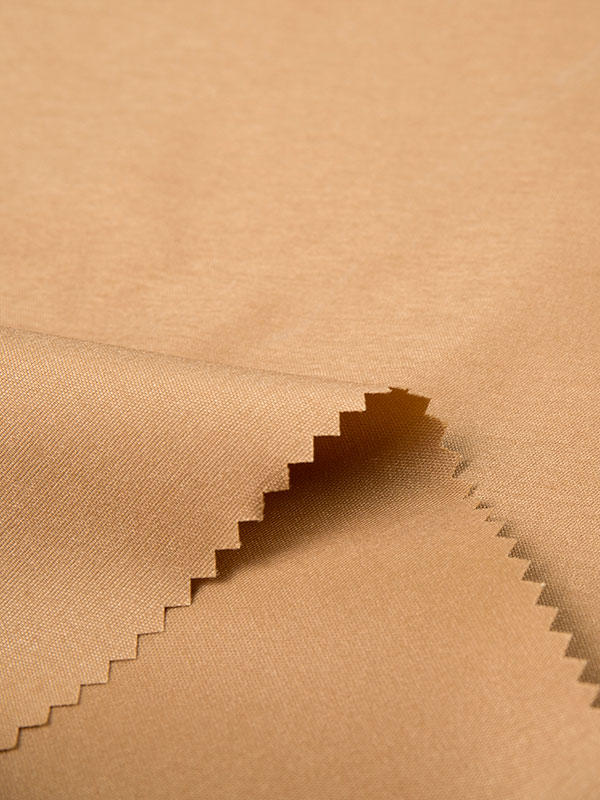

1. Material characteristics of 200D Single-side Cloth Automobile fabric

200D Single-side Cloth Automobile fabric is a high-density polyester fiber fabric. Its "200D" means that the thickness of the yarn is 200 Denier, which makes the fabric have good strength and wear resistance. The thickness of the fabric is 0.52 mm and the weight is 130 ± 5g/㎡. This specification of fabric has a certain thickness and maintains the characteristics of lightness.

The surface of the fabric is specially treated to enhance its adhesion to PVC leather. The treated fabric not only improves the surface roughness, but also improves its chemical properties, allowing the fabric to form a stronger bond with PVC leather.

2. Characteristics and functions of PVC leather

PVC leather is a synthetic material commonly used in automotive interiors, and its main component is polyvinyl chloride (PVC). PVC leather has stain resistance, easy cleaning and wear resistance, which makes it widely used in car seats, door panels and dashboards.

The surface of PVC leather usually has a certain degree of roughness, which provides a good adhesion basis for bonding with 200D Single-side Cloth Automobile fabric. Since the chemical properties of PVC leather match the surface treatment of 200D Single-side Cloth Automobile fabric, this combination can effectively improve the bonding strength.

3. Formation mechanism of strong bonding strength

The strong bonding strength of 200D Single-side Cloth Automobile fabric and PVC leather is mainly due to the following mechanisms:

Surface treatment and roughness: The surface of 200D Single-side Cloth Automobile fabric is specially treated to give it good adhesion. When combined with PVC leather, the surface treatment of the fabric can form good contact with the roughness of the leather, increasing the contact area and thus enhancing the bonding strength.

Chemical compatibility: The chemical compatibility between 200D Single-side Cloth Automobile fabric and PVC leather is also a key factor. The chemical properties of the two have been optimized, so that the fabric and leather can form a stable chemical bond when bonded, further improving the bonding strength.

Lamination process: The bonding of 200D Single-side Cloth Automobile fabric and PVC leather usually adopts the lamination process. This process combines the fabric and leather tightly together through high temperature and high pressure treatment.

Physical adhesion: The bonding of fabric and leather also depends on physical adhesion. The fiber structure of 200D Single-side Cloth Automobile fabric can form a small mechanical bite force on the surface of the leather, further enhancing the adhesion of the two.

4. Advantages in application

The strong bonding strength of 200D Single-side Cloth Automobile fabric and PVC leather brings significant advantages in practical applications:

Durability: The strong bonding strength improves the overall durability of the material, making it less likely for the car interior to delaminate or wear in long-term use. This durability is particularly important for parts such as car seats, door panels and dashboards.

Aesthetics: Strong bonding ensures that the fabric and leather are tightly and evenly bonded, avoiding delamination or wrinkling that affects the visual effect. This aesthetic has a direct impact on the quality of high-end car interiors.

Comfort: In car seats and other parts, strong bonding ensures the fit between fabric and leather, improving the comfort of the seat. This comfort can enhance the riding experience and play an important role in user satisfaction.

English

English 中文简体

中文简体 Français

Français Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-2.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)