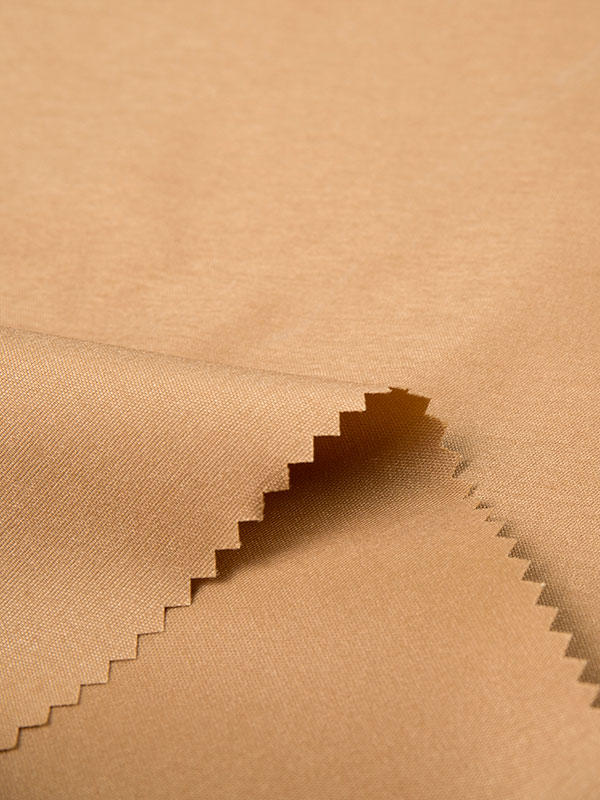

I. Overview of adhesive types

Color Interlining adhesives can be mainly divided into the following types:

Temporary adhesives: Temporary adhesives are usually used for fabrics that need to be adjusted or replaced multiple times. They provide a temporary bonding effect after heating, but they are not permanently fixed. This type of adhesive is suitable for the fitting stage or design stage, allowing designers to flexibly adjust samples.

Permanent adhesives: Permanent adhesives form a strong bond after heating, which can durably fix Color Interlining to the fabric. They are suitable for most garments, especially formal garments that require high durability. Choosing permanent adhesives can ensure the stability of the garment during wearing and washing.

Repositionable adhesives: The characteristic of repositionable adhesives is that they can be adjusted multiple times after heating. This type of adhesive is very suitable for delicate processes that require precise positioning, especially in cases where certain precision designs are required, such as decorative sewing or splicing.

II. How to choose the right adhesive

The following key factors should be considered when choosing a suitable adhesive:

Fabric characteristics: Different fabrics have different requirements for adhesives. For thin and delicate fabrics, temporary adhesives or repositionable adhesives are recommended to avoid damage to the fabric due to excessive heat. For heavy fabrics, permanent adhesives can be used to enhance structural support.

Garment use: Choose the right adhesive based on the purpose of the garment. For example, daily wear may not require particularly high durability, and temporary adhesives or repositionable adhesives can meet the requirements. For high-end suits or jackets, using permanent adhesives can better ensure the overall effect and durability of the garment.

Washing and care requirements: When choosing an adhesive, be sure to check the relevant washing and care instructions. Some permanent adhesives may fail in high-temperature washing or dry cleaning, while temporary adhesives may completely lose their effectiveness during the washing process. Therefore, the selected adhesive should match the washing and care requirements of the garment.

Ease of operation: The ease of operation of the adhesive is also an important consideration. For beginners or small-scale production, using easy-to-operate temporary adhesives or repositionable adhesives can reduce the occurrence of errors. Professional garment factories can choose more complex permanent adhesives to improve the overall quality of the garment.

Production process: Different production processes also have different requirements for adhesives. On an efficient assembly line, choosing a fast-curing permanent adhesive can improve production efficiency, while in small batches or handmade production, using a repositionable adhesive is more flexible.

English

English 中文简体

中文简体 Français

Français Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-2.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)