Manufacturing high and low elasticity medical cloth involves many key technical points, which directly affect the performance, quality and application of medical cloth in the medical field. The following are some key technical points for manufacturing high and low elasticity medical cloth:

Material selection: The first key point in manufacturing high and low elasticity medical cloth is to select the appropriate material. Commonly used materials include elastane, natural fibers and synthetic fibers. These materials need to meet medical standards, ensure they are harmless and non-allergenic, and have the required elasticity and durability.

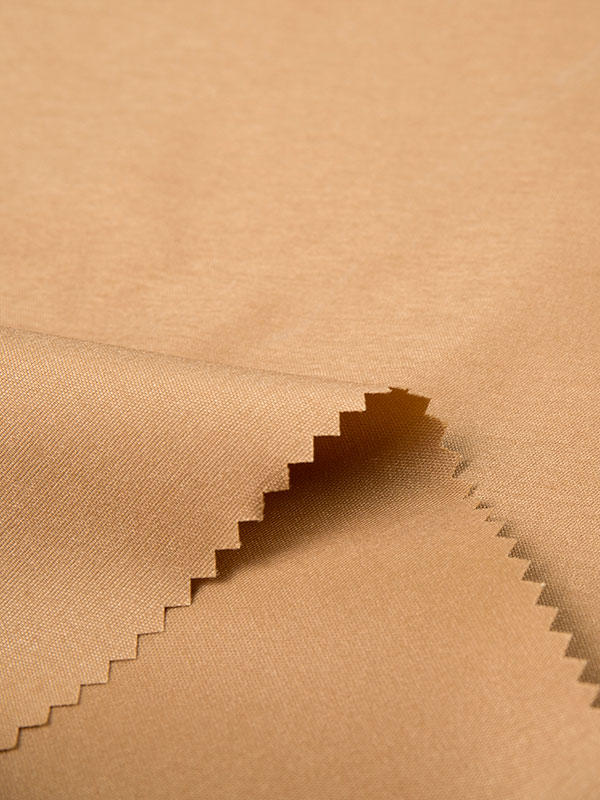

Textile technology: It is crucial to use textile technology to manufacture high and low elasticity medical cloths. Different textile processes can produce different fiber arrangements and textures, thereby affecting the elasticity and adaptability of medical cloths. Key textile technologies include knitting, woven and nonwoven manufacturing.

Elasticity fiber processing: Elastic fiber processing is a key step to ensure that medical cloth has high and low elasticity. This may involve introducing elasticity fibers during the manufacturing process, or using subsequent processing processes to enhance the elasticity of the fibers.

Texture design: The texture design of high and low elasticity medical cloth directly affects its elasticity and adaptability. By cleverly designing the texture, different elasticities in different parts can be achieved to meet the specific needs of medical applications.

Surface treatment: The surface treatment of medical cloth is crucial to improve breathability, antibacterial properties and comfort. Coatings, waterproofing, or other surface technologies can improve the performance of medical fabrics.

Medical Standard Compliance: One of the key points in manufacturing high and low stretch medical fabrics is ensuring that the product complies with relevant standards and regulations in the medical industry. This includes comprehensive compliance checks on the quality and safety of materials, production processes and final products.

Durability testing: To ensure that medical cloths maintain their performance over long periods of use, durability testing is essential. This may include things like tensile testing, abrasion testing and post-cleaning performance evaluation.

Adaptability and Comfort Assessment: Evaluating the adaptability and comfort of medical fabrics is critical for their use in medical settings. This may involve testing the fabric's feel, breathability, and irritation to the skin.

Production process control: During the entire production process of manufacturing high and low elasticity medical cloths, precise process control is the key to ensuring product consistency and quality. Automation technology, quality inspection and production process optimization are all factors to consider.

English

English 中文简体

中文简体 Français

Français Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-2.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)