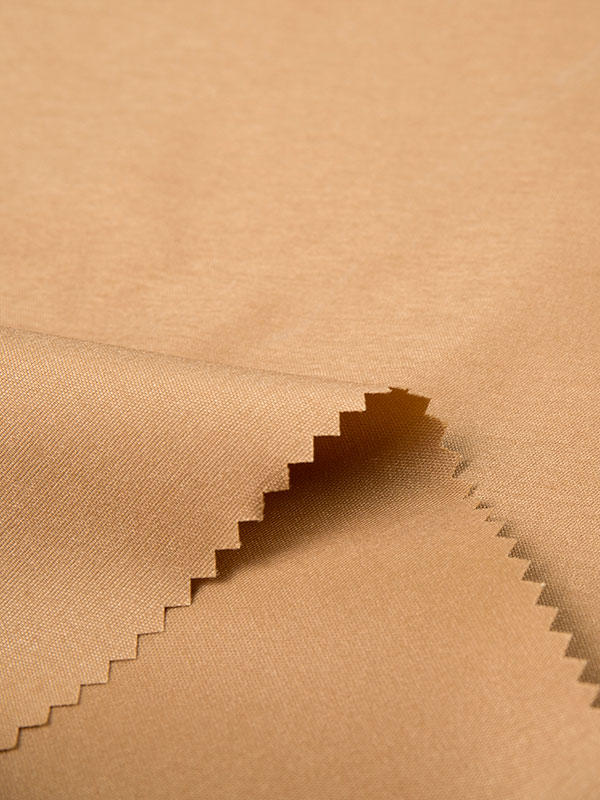

The production cost of GRS Recycled Fabric is significantly different from that of traditional fabrics. These differences are mainly reflected in the source of raw materials, production process, environmental certification requirements and market demand.

First of all, from the perspective of raw material sources, the raw materials of GRS Recycled Fabric mainly come from recycled materials such as waste textiles and plastic bottles. The collection, classification and reuse of these raw materials require additional cost investment, including recycling logistics costs, classification and processing costs, and the research and development and production costs of recycled fibers. In contrast, the raw materials of traditional fabrics are mostly virgin fibers, such as cotton and wool, which have relatively low acquisition costs and relatively stable supply chains.

Secondly, in the production process, the production of GRS Recycled Fabric requires more complex processes and technical support. Since the physical and chemical properties of recycled fibers are different from those of virgin fibers, more technical adjustments and optimizations are required in the production links such as spinning, weaving, printing and dyeing. These technical adjustments and optimizations not only increase production costs, but also increase the difficulty and complexity of production. In addition, the production of GRS Recycled Fabric also needs to meet strict environmental protection requirements, such as wastewater treatment, exhaust gas emissions, etc., which also requires additional environmental protection equipment and investment.

Thirdly, the environmental certification requirements of GRS Recycled Fabric are also an important factor to rising production costs. GRS certification requires companies to meet certain standards in terms of raw material sources, production processes, social responsibilities and environmental protection practices, which requires companies to make a lot of investments in personnel training, equipment upgrades, management improvements, etc. At the same time, GRS certification also requires companies to pay certain certification fees and annual inspection fees, which also increase the production costs of companies.

Finally, from the perspective of market demand, the market demand for GRS Recycled Fabric is gradually increasing, but its market share is still relatively small compared to traditional fabrics. This means that companies need to invest more resources and energy to promote and publicize GRS Recycled Fabric to attract more consumers and customers. The cost of this kind of market promotion and publicity is also a factor to the rising production costs of GRS Recycled Fabric.

English

English 中文简体

中文简体 Français

Français Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-2.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)