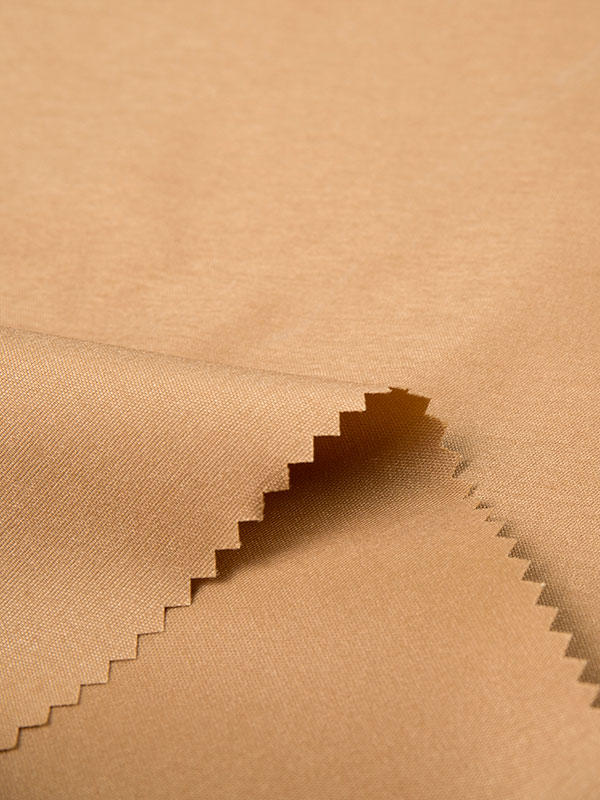

The recycling process of GRS Recycled Fabric is a complex and sophisticated process that ensures that waste materials are effectively converted into high-quality recycled fabrics. The following is a detailed analysis of the recycling process of GRS Recycled Fabric:

1. Recycling and Sorting

The recycling process of GRS Recycled Fabric begins with the collection of waste items. These waste items may be generated in household, commercial, industrial or institutional facilities, such as waste clothing, curtains, carpets, etc. The recycled materials will undergo strict sorting and screening to ensure that only waste polyester fibers and other polymer materials that meet GRS standards are used for subsequent production.

2. Pretreatment

Before the recycled materials are sent to the production plant, they will undergo a series of pretreatment steps, including sorting, washing and drying. These steps are designed to remove impurities and contaminants in the waste materials and provide clean raw materials for the subsequent recycling process.

3. Physical Recycling

The main recycling method of GRS Recycled Fabric is physical method. This method uses melt regeneration technology to reheat the waste polyester material to a molten state, and then converts it into new fibers through processes such as spinning. The advantages of physical recycling are that its production process is simple, cost-effective, and the physical and chemical properties of the raw materials can be kept unchanged.

Specifically, physical recycling includes the following steps:

Melting: heating the cleaned waste polyester material to a molten state.

Filtration: removing impurities and unmelted particles in the molten material through filtering equipment.

Spinning: passing the molten material through a spinneret to form fibers.

Stretching and curling: stretching and curling the fibers to improve their physical properties.

IV. Chemical recycling

Although the physical method is currently the dominant method for recycling GRS Recycled Fabric, the chemical method is also gradually developing. Chemical recycling mainly depolymerizes waste polyester materials into polymer monomers or polymer intermediates through chemical reactions, and then regenerates polymerization and melt spinning. This method has lower requirements for sorting and cleaning of waste polyester, but the production cost is relatively high.

V. Quality control and testing

In the production process of GRS Recycled Fabric, quality control and testing are crucial links. Manufacturers need to ensure that the recycled and reused fibers meet the requirements of GRS standards, including the physical properties, chemical composition and environmental performance of the fibers. In addition, the production process needs to be strictly monitored to ensure the implementation of environmental protection standards.

English

English 中文简体

中文简体 Français

Français Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)